In wastewater treatment plants, biomass solids is a byproduct of the treatment process. It consists of a mixture of organic and inorganic materials, microorganisms, and bound water. Over time, sludge can age and transform into what is known as “old sludge.” Understanding the characteristics and challenges associated with old sludge is crucial for effective wastewater treatment.

Detecting Old Sludge

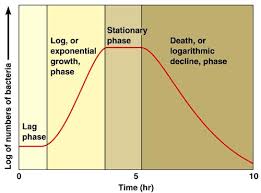

Old sludge refers to biomass that has been in the system for an extended period. It is characterized by a higher proportion of dead microbial cells, reduced microbial activity, and an accumulation of extracellular polymeric substances (EPS) which eventually are consumed leading to “fines” or turbidity after biological solids settle. These changes can impact the settling properties and overall performance of the treatment process.

- Fast settling biosolids in SV30 test with increased tubidity in supernatant and possibly floating pin floc

- Low OUR or SOUR numbers in respiration rate tests which means lower rates of microbial growth & cell division

- In microscopic exam the floc size starts to decrease and you see indicator organisms moving toward rotifers, testate amoeba, and other multicellular metazoa

- Operating a low F/M or high MCRT for extended periods

Problems operating at very low F/M and high MCRT

- Loss of ideal floc structure – leading to higher tubidity and TSS over the clarifier weir

- Decreased aeration efficiency as inactive (dead) biomass and inorganic solids increase. While D.O. may be high, the oxygen transfer rate decreases increasing utility costs

- Potential bulking related to low F/M filaments – lack of sufficient soluble BOD for normal biomass growth starts to favor high surface area filamentous organisms that do not form floc

- High MCRT with oil & grease can create an ideal environment for Nocardia type organisms with associated foaming

The solution

The soluiton to old sludge is actually very simple: Increase Wasting Rates. If solids stabilization in digesters is too slow, there are treatment strategies to increase digester both aerobic and anaerbic efficiency. If solids handling is limited by the physical dewatering equipment, you should check your polymer chemistry – better polymer selection and dosing can greatly improve dewatering.