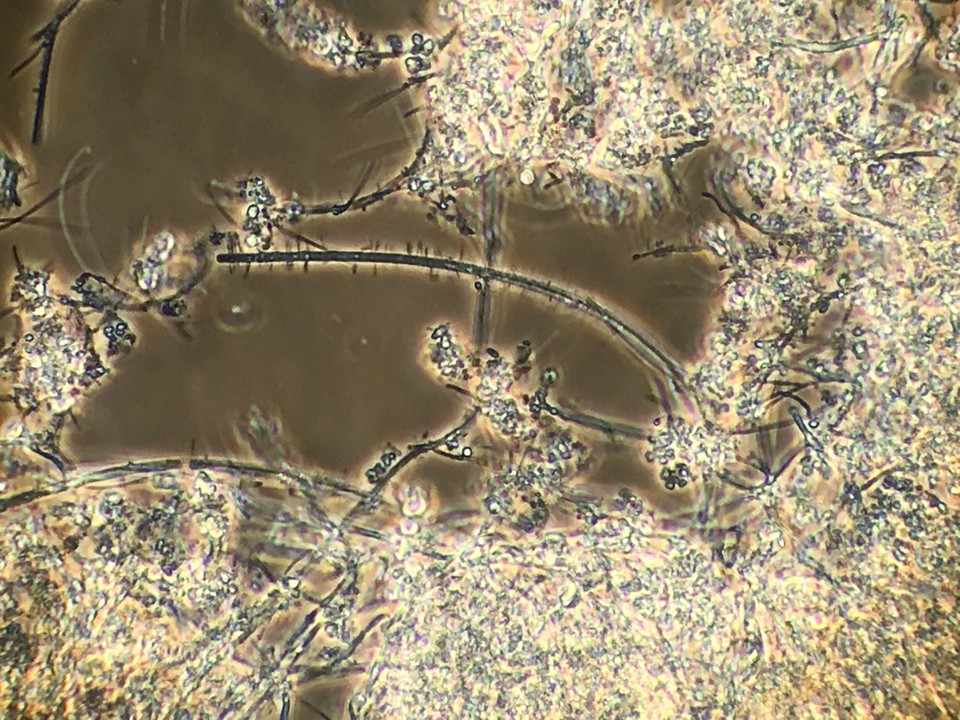

Industrial mature MLSS with filaments and floc formers within normal range. 400x Phase Contrast.

Mixed Liquor Suspended Solids (MLSS) are the heart of biological wastewater treatment—and how well they settle can make or break plant efficiency. Poor settleability leads to solids carryover, elevated TSS in effluent, and headaches for operators. Fortunately, there are proven strategies to improve compaction, settleability, and overall system resilience.

Optimize Microbial Population Dynamics

A balanced microbial community improves floc structure and settleability. Here’s how:

- Control filamentous bacteria: Monitor key contributors like Sphaerotilus, Thiothrix, and Nocardia. Target control with selectors, DO management, and nutrient dosing.

- Promote EPS-producing microbes: Encourage species that enhance floc cohesion—excess exopolysaccharides (EPS) can improve compaction but should be balanced to avoid slime bulking.

- Manage PAO and GAO competition: Select for PAOs to support phosphorus removal and sludge settleability, using anaerobic selectors and F:M ratio adjustment.

Fine-Tune Process Parameters

Small tweaks to operational conditions can yield big results:

- Control DO and aeration intensity: Avoid over-aeration, which fragments flocs. Keep DO in the optimal range (typically 1.5–2.0 mg/L).

- Optimize SRT and HRT: Short SRTs may reduce floc maturity; longer SRTs can improve floc density but risk aging. Dial it in based on observations and system goals.

- Adjust MLSS concentration: High MLSS levels can improve compaction but reduce settleability. Monitor SV30 and SVI to guide adjustments.

Leverage Molecular Tools for Community Insights

Advanced testing reveals microbial fingerprints and actionable insights:

- Use Microbial Community Analysis: Identify filamentous abundance and key functional groups.

- Data Analysis: Track diversity shifts and microbial health over time.

- Integrate findings into process control: Align community structure with settling performance for smarter interventions.

Physical and Chemical Enhancements

When biology isn’t enough, tech comes to the rescue:

- Chemical aids: Use polymers or metal salts (e.g., alum, ferric chloride) judiciously to improve flocculation.

- Lamella plates and tube settlers: Increase surface area and improve solids removal efficiency.

- Hydraulic adjustments: Modify feed distribution and weir configurations to enhance settling zones.

Metrics to Monitor

To evaluate success, regularly track:

| Parameter | Ideal Range | Insight |

| Sludge Volume Index (SVI) | 80–150 mL/g | Indicates good settleability |

| SV30 (30-min settling test) | Site-specific | Assesses short-term compaction |

| Microscopic floc structure | Compact, with low filaments | Visual check of health |

| EPS concentration | Balanced | Too little = fragile flocs; too much = slime bulking |

How Aster Bio Supports Optimal Settling Performance

Achieving the ideal settling range requires more than trial and error—it calls for microbiological precision. Aster Bio specializes in molecular testing and microbial community analysis that complements and expands on microscopic exam. By identifying key organisms, tracking filamentous bacteria, and uncovering microbial shifts before performance drops, operators can take proactive steps to maintain stability.

With targeted bioaugmentation products and data-driven insights, Aster Bio empowers facilities to enhance floc structure, reduce bulking risk, and fine-tune system conditions for consistent settleability—all without guesswork.