For aerobic wastewater treatment systems, maintaining Dissolved Oxygen levels is key to efficient treatment. Operating a combination of blowers or surface aerators represents a significant use of energy/utility costs. Picking the correct aeration system and placement impacts treatment efficiency and operation costs.

Water Factors Impacting Oxygen Transfer Efficiency

- Temperature – O2 is more soluble at lower temperatures

- Air pressure (barometer)

- Oxygen purity – air is approximately 19%, high purity oxygen systems are much higher – more O2 gas in the bubble = more oxygen transferred into the water.

- Water pollutants – BOD/COD especially surfactants impact O2 transfer efficiency

- MLSS – higher solids have endogenous respiration but also can impact oxygen transfer to microorganisms.

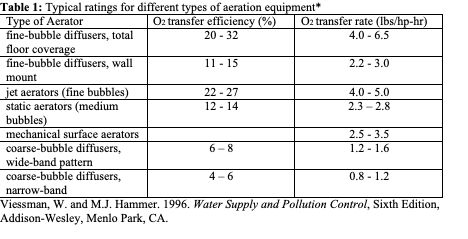

- The aeration system itself impacts OTE

Two-Film Theory of Oxygen Transfer

Making it simple

The more surface area and contact time between gas and water = better transfer of the gas into the water. This is key to all aeration system calculations.

The Impact of Air Bubble Size on Dissolved Oxygen in Wastewater Treatment

Wastewater treatment is a critical process for maintaining clean water and protecting the environment. One of the key components of this process is aeration, which involves introducing air bubbles into the water to increase the dissolved oxygen (DO) levels. The size of these air bubbles plays a significant role in the efficiency of oxygen transfer. It is good to explore how different bubble sizes—coarse, fine, and nano—impact dissolved oxygen in wastewater treatment.

Coarse Bubble Aeration

Coarse bubble aeration involves the use of larger air bubbles, typically ranging from 6.4 to 13 mm in diameter1. These bubbles are released from diffusers at the bottom of the treatment tank and rise rapidly to the surface. While coarse bubbles are effective at mixing and churning the wastewater, they have a lower oxygen transfer efficiency (OTE) compared to finer bubbles. This is because the larger surface area of coarse bubbles results in less contact time with the water, leading to lower oxygen dissolution1. Despite this, coarse bubble aeration is still widely used in certain applications, such as grit chambers and equalization basins, where mixing is more critical than oxygen transfer1.

Fine Bubble Aeration

Fine bubble aeration, on the other hand, uses smaller bubbles, typically measuring 1 to 3 mm in diameter2. These bubbles are produced by diffusers with fine pores, which create a higher surface area for oxygen transfer. Fine bubbles rise more slowly through the water, allowing for a longer contact time and higher oxygen dissolution. This results in a higher OTE, often exceeding 2%2. Fine bubble aeration is commonly used in both primary and secondary treatment processes, where efficient oxygen transfer is essential for the breakdown of organic matter by aerobic bacteria2.

Micro & Nano Bubble Aeration

Micro & nano bubble aeration is a newer form of aeration technology with even smaller bubble sizes than fine bubble diffusers. These bubbles are incredibly small, nanobubbles are usually less than 100 nanometers in size. Micro bubbles are significantly larger at 1,000 – 100,000 nanometers in size (1 micrometer = 1,000 nanometers).

Due to their tiny size, nanobubbles exhibit unique properties that significantly enhance oxygen transfer. They remain suspended in the water for extended periods, providing extended contact time with surrounding water. Nanobubbles have a high OTE, often surpassing 85%. This makes them highly effective for treating hypoxic environments and improving water quality.

Not eliminated COD or BOD should be used to calculate the actual organics carbonaceous oxygen requirement, but the net consumed oxygen in the biodegradable COD: CO = bCOD * (1 – YH)

Thank you … very good point.