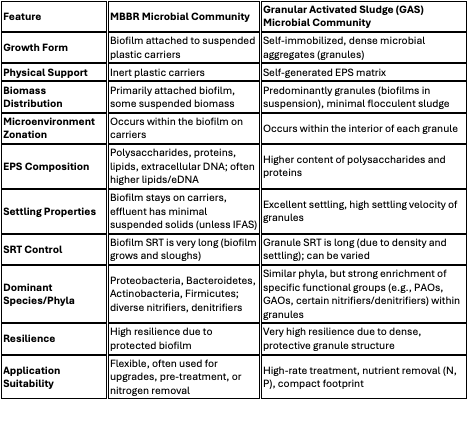

Both Moving Bed Biofilm Reactor (MBBR) and Granular Activated Sludge (GAS) systems are advanced wastewater treatment technologies that have increased biomass density than conventional activated sludge, their distinct operational principles lead to significant differences in the structure and function of these communities.

Moving Bed Biofilm Reactor (MBBR) Microbial Community:

MBBR systems utilize small, specially designed plastic carriers that are suspended and move freely within the reactor. Microorganisms grow as a biofilm on the surface of these carriers.

Key Characteristics of MBBR Microbial Communities:

- Attached Growth (Biofilm Dominant): The defining characteristic of MBBR is the predominance of attached biomass in the form of biofilms on the carriers. This provides a stable environment for microbial growth and retention.

- High Biomass Concentration: The carriers allow for a significantly higher concentration of active biomass within the reactor compared to conventional activated sludge systems.

- Diverse Microenvironments: Within the biofilm, oxygen gradients can develop, leading to the formation of both aerobic and anoxic/anaerobic microenvironments. This enables the coexistence of diverse microbial populations, including:

- Aerobic Heterotrophs: Responsible for the degradation of organic matter (COD, BOD). Common phyla include Proteobacteria (e.g., Gammaproteobacteria, Betaproteobacteria), Bacteroidetes, Actinobacteria, and Firmicutes.

- Nitrifying Bacteria: Slower-growing nitrifiers (Ammonia-Oxidizing Bacteria – AOB like Nitrosomonas, and Nitrite-Oxidizing Bacteria – NOB like Nitrobacter, Nitrospira) thrive due to their longer sludge retention time (SRT) within the biofilm, leading to stable nitrification even under fluctuating hydraulic loads. Both AOB & NOB preferentially grow on the surface of the biofilm where D.O. is highest.

- Denitrifying Bacteria: Facultative anaerobic bacteria that can perform denitrification (converting nitrates to nitrogen gas) are found in the anoxic zones within the biofilm. These can include a variety of heterotrophic denitrifiers (e.g., Denitratisoma, Thermomonas, Flavobacterium).

- Anammox Bacteria: In some specialized MBBR configurations (e.g., anaerobic MBBR or specific nitrogen removal setups), anaerobic ammonium-oxidizing (Anammox) bacteria (Candidatus Brocadia) can be enriched, contributing to highly efficient nitrogen removal.

- Extracellular Polymeric Substances (EPS): Biofilms in MBBRs are rich in EPS, which consist of polysaccharides, proteins, lipids, and extracellular DNA. EPS provide structural integrity, protect the microbial cells from environmental stresses, and facilitate the adsorption of pollutants. MBBR biofilms may have higher levels of lipids and extracellular DNA compared to activated sludge flocs.

- Resilience to Shock Loads: The stable biofilm structure makes the MBBR microbial community more resilient to fluctuations in influent quality, hydraulic loading, and even some toxic compounds, as the protected cells within the biofilm can recover more easily.

- Lower Sludge Production: Often, MBBR systems produce less excess sludge compared to conventional activated sludge.

Granular Activated Sludge (GAS) Microbial Community:

Granular activated sludge systems promote the formation of dense, self-immobilized microbial aggregates called “granules” without the need for artificial carriers. These systems are typically operated in Sequencing Batch Reactors (SBRs) or continuous flow reactors with specific hydrodynamic conditions.

Key Characteristics of GAS Microbial Communities:

- Self-Immobilized Aggregates (Granules): The defining feature is the formation of robust, dense, and spherical or irregular microbial granules. These granules are essentially “biofilms in suspension.”

- Layered Structure and Zonation: Granules develop a distinct layered structure with different microbial populations thriving in different zones based on oxygen availability. This often creates:

- Aerobic Outer Layer: Dominated by aerobic heterotrophs for organic matter degradation and nitrifying bacteria.

- Anoxic/Anaerobic Inner Core: Favors denitrifying bacteria, polyphosphate-accumulating organisms (PAOs), and glycogen-accumulating organisms (GAOs). This inherent zonation within a single granule allows for simultaneous nitrification-denitrification and enhanced biological phosphorus removal (EBPR).

- High EPS Content (Polysaccharide-Rich): GAS granules are characterized by a significantly higher content of polysaccharides and proteins in their EPS matrix compared to activated sludge flocs and MBBR biofilms. This high EPS content is crucial for the structural stability, density, and excellent settling properties of the granules.

- Coexistence of Functional Groups: The unique internal structure allows for the stable coexistence of slow-growing organisms (like nitrifiers and PAOs) and faster-growing heterotrophs.

- Specific Granulation-Promoting Microorganisms: The formation and stability of granules are influenced by specific microbial interactions. While diverse, certain bacteria might be more prevalent during granulation (e.g., certain Accumulibacter species for phosphorus removal).

- Higher Microbial Diversity (often): Due to the longer and more varying effective SRT within the granules, GAS systems often exhibit higher microbial diversity compared to conventional activated sludge. Immigration from influent wastewater appears to be less impactful on the core granular community compared to flocculent sludge.

- Excellent Settling Properties: The dense nature of the granules leads to superior settling velocities, enabling higher hydraulic loading rates and more compact reactor designs.

- Resilience and Robustness: Similar to MBBR biofilms, the granular structure provides significant protection against shock loads, toxic compounds, and environmental fluctuations.

In essence, while both systems leverage microbial aggregates for efficient wastewater treatment, MBBR relies on a robust attached biofilm on a carrier, providing stability and surface area. GAS, on the other hand, engineers a self-forming granular aggregate, offering exceptional settling characteristics and internal zonation for multi-process treatment within a single particle. These structural differences directly influence the composition, diversity, and functional capabilities of their respective microbial communities.