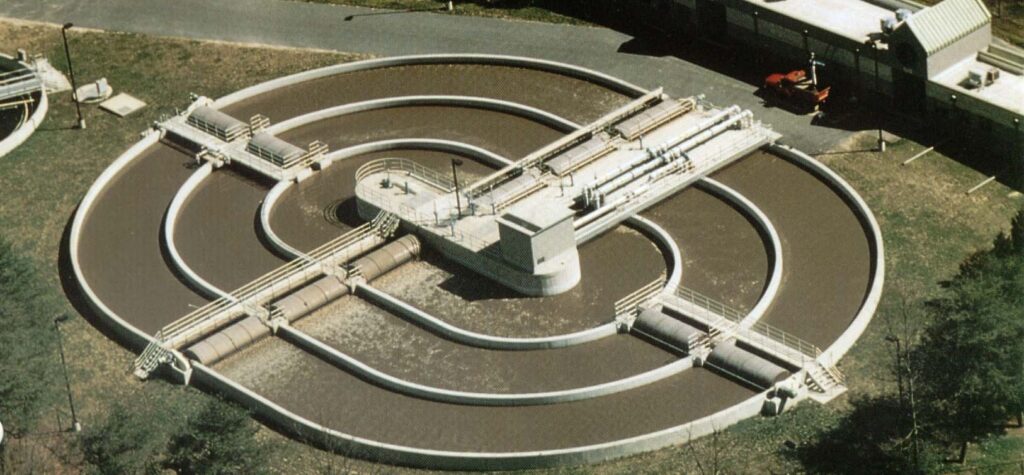

Oxidation Ditch from www.engineeringfundamentals.net.

Simultaneous Nitrification-Denitrification (SNdN) is an advanced process used in wastewater treatment to remove nitrogen compounds. Here’s a detailed look at how it works:

Process Overview:

- Nitrification: This involves the biological oxidation of ammonia (NH₃) to nitrate (NO₃⁻) through two steps:

- Ammonia to Nitrite (NO₂⁻): Carried out by ammonia-oxidizing bacteria (AOB) such as Nitrosomonas.

- Nitrite to Nitrate (NO₃⁻): Performed by nitrite-oxidizing bacteria (NOB) such as Nitrospira. Both steps require oxygen and the reactions are aerobic.

- Denitrification: In this step, nitrate (NO₃⁻) & (NO₂⁻) are reduced to nitrogen gas (N₂), which is then released into the atmosphere. This process is carried out by denitrifying bacteria under anoxic (low oxygen) conditions, using organic carbon as an electron donor.

Key Features of SNdN:

- Single Reactor: Unlike traditional methods that separate nitrification and denitrification into different stages or reactors, SNdN combines both processes in one reactor.

- Oxygen Gradient: The reactor maintains different zones with varying oxygen levels. High dissolved oxygen (DO) near the oxygen source supports nitrification, while lower DO areas farther away facilitate denitrification.

- Microbial Communities: The system supports a mixed microbial community that can simultaneously perform both nitrification and denitrification.

Advantages:

- Space and Cost Efficiency: SNdN reduces the need for multiple reactors, saving space and construction costs.

- Energy Savings: Less energy is required for aeration compared to conventional systems.

- High Nitrogen Removal Efficiency: Combining both processes in one reactor can lead to effective nitrogen removal from wastewater.

Challenges:

- Oxygen Control: Maintaining the correct oxygen levels is crucial for the balance between nitrification and denitrification.

- Process Stability: Ensuring stable operation and microbial community balance can be challenging.

- Foaming and Sludge Issues: Potential for foaming and sludge bulking if not properly managed.

Design Considerations:

- Reactor Type: Common types include activated sludge (usually Oxidation Ditch), aerobic biofilm reactors, MBBR, granular sludge, and sequencing batch reactors (SBRs). In MBBR and granular sludge the anoxic zone is deeper in the biofilm while the aerobic zone is on the surface. The activated sludge and SBR systems are operated with aerobic zones or times followed by anoxic.

- DO & ORP Monitoring: Continuous monitoring and control systems to maintain appropriate levels.

- Microbial Balance: Strategies to ensure a balanced microbial community for effective nitrification and denitrification.