Anaerobic digesters rely on a complex consortium of microorganisms for converting biosolids into methane gas and carbon dioxide. The community includes both bacteria and archaea. The first steps in the process rely on the action of bacteria, while the final steps yielding methane require archaea. For a thriving archaea population, the digester must convert complex organic solids into acetate, CO2, and H2. While normally stable, anaerobic digesters may experience bottlenecks. Various technologies exist to relieve these bottlenecks. This post discusses the opportunity to use hydrolytic enzymes to speed up complex polymer degradation into soluble organics used by acid forming bacteria.

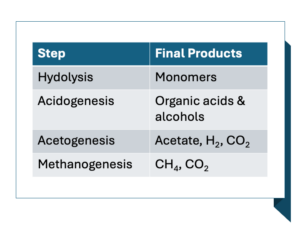

Steps in Anaerobic Digester Process

- Hydrolysis: Complex organic materials like carbohydrates, proteins, and fats are converted into simpler soluble molecules such as sugars, amino acids, and fatty acids that readily cross the cell walls of acid forming (fermentative) bacteria.

- Acidogenesis: The soluble molecules produced in hydrolysis are further broken down by acidogenic bacteria into volatile fatty acids, alcohols, hydrogen, and carbon dioxide.

- Acetogenesis: Longer chain volatile fatty acids and alcohols are converted into acetic acid, hydrogen, and carbon dioxide by acetogenic bacteria.

- Methanogenesis: Methanogenic archaea utilize acetic acid, hydrogen, and carbon dioxide as inputs for producing methane and carbon dioxide.

Using Enzymes for Optimizing Hydrolysis

Exoenzymes are the enzymes required to convert complex organic compounds into forms that can be taken into bacterial cells for further metabolism. In a stable digester, you have sufficient hydrolytic enzymes to solubilize all the influent organics. However, under high solids loadings you may not have sufficient time for enzyme formation by indigenous hydrolytic bacteria. This results in an increase in organic acids and decrease in methane yield (solids stabilization). The concept of using enzymes requires that we know which polymers are not being hydrolyzed and matching the enzyme(s) to address the bottleneck. The enzymes must be able to function at the pH, temperature, and on substrates present in the digester. By adding enzymes, you reduce the time required for hydrolysis and allow for increased formation of acetate, H2, and CO2 used by methanogens.

Key points to consider before using enzymes

- Evaluate the digester to see if hydrolysis step is the bottleneck

- What substrates have insufficient rates of hydrolysis – examples include long chain fatty acids (FOG), cellulose, proteins, and lignin

- What enzyme complex is needed.

- Check to ensure other parameters including temperature, pH, alkalinity, and micronutrients are optimal for methanogen growth.