In biological wastewater treatment process efficiency relies on the health and stability of the microbial flocs— aggregates of bacteria, adsorbed organics, and inorganics. When these flocs break apart, a problem known as deflocculation occurs. This phenomenon is a major headache for plant operators, as it directly impacts water quality and separation processes.

What is Deflocculation?

Simply put, deflocculation is the disruption and breakdown of biological flocs (or activated sludge) into smaller, dispersed particles or individual cells.

In a healthy wastewater treatment system, microorganisms cluster together to form large, dense flocs. This structure is held together primarily by a sticky matrix of biopolymers known as Extracellular Polymeric Substances (EPS).

The floc structure is vital because it:

- Enhances settling: Large, heavy flocs settle quickly in the clarifier, allowing for easy separation of clean water from the sludge.

- Improves removal: The high surface area and structure allow for efficient adsorption and consumption of pollutants.

When deflocculation occurs, these small particles no longer settle well, leading to:

- High Turbidity: The treated effluent becomes cloudy.

- Poor Sludge Settling: Sludge blankets are difficult to form, and solids “carry over” into the clean effluent.

- Loss of Biomass: Valuable microorganisms are washed out of the system, reducing treatment capacity.

The Glue That Holds It Together: Extracellular Polymeric Substances (EPS)

To understand floc disruption, you must understand EPS. EPS is the “glue” of the floc, primarily composed of polysaccharides (sugars), proteins, humic substances, and nucleic acids secreted by the bacteria. It provides the structural integrity, acts as a protective barrier, and facilitates substrate uptake.

Deflocculation is essentially the chemical or physical disruption of this EPS matrix.

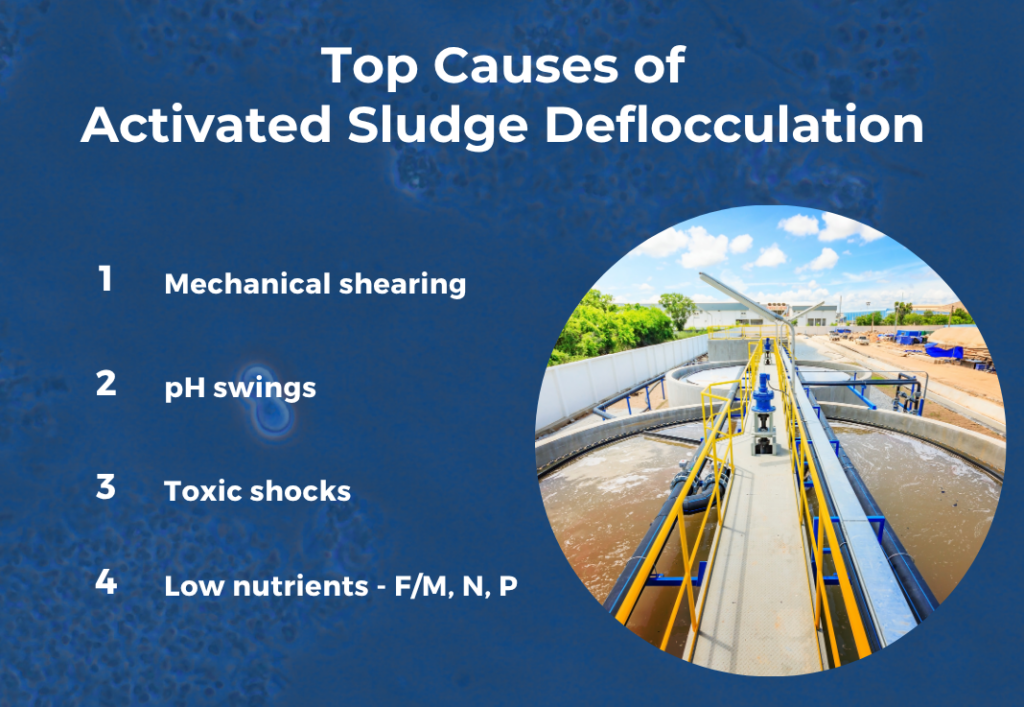

Common Causes of EPS Disruption and Deflocculation

The health of the EPS matrix is highly sensitive to changes in the environment. Here are the most common factors that lead to its disruption and subsequent deflocculation:

Mechanical Shear and Hydraulic Stress

The physical forces within the treatment plant are a frequent cause.

- Excessive Mixing: High-intensity mixing in aeration basins or sludge pumps can physically rip the flocs apart.

- Pumping/Piping: Flocs are fragile. Passing them through high-shear pumps, narrow pipes, or turbulent flow sections can induce stress that breaks the weak EPS bonds.

- Solution: Optimize mixing speed and minimize hydraulic turbulence within the plant, especially when transferring sludge.

pH Swings

Common wastewater microorganisms and the EPS they produce thrive within a relatively narrow, neutral pH range (typically 6.5 to 8.5).

- Extreme pH: Both very high (alkaline) and very low (acidic) pH levels can solubilize or denature the EPS proteins and polysaccharides. This effectively dissolves the glue that holds the floc together.

- Cause: Industrial discharges or uncontrolled biological reactions (like excessive nitrification/denitrification).

- Solution: Continuous pH monitoring and control via chemical addition (e.g., lime or acid) is critical.

Toxic Shock Loads

The sudden introduction of toxic substances into the wastewater stream is a rapid deflocculation culprit.

- Inhibitory Compounds: Heavy metals, biocides, strong oxidizing agents (like chlorine), and high concentrations of certain organic chemicals can kill or severely stress the bacteria. Stressed or dead bacteria cease EPS production, and existing flocs degrade quickly.

- Solution: Pre-treatment programs for industrial dischargers and robust influent monitoring systems are essential to catch and divert toxic loads.

Nutrient Imbalances (F/M Ratio and Limiting Nutrients)

The ratio of Food to Microorganisms (F/M) and the presence of essential nutrients (like nitrogen and phosphorus) dictate how the bacteria behave.

- Low F/M (Starvation): When the food supply drops too low, microorganisms may enter an endogenous phase (starvation). They begin to break down their own stored resources, including parts of the EPS, leading to a weaker, more dispersed floc structure.

- Limiting Nutrients: A deficiency in key nutrients (N or P) can hinder the bacteria’s ability to produce the necessary EPS for floc formation.

- Solution: Maintain the optimum F/M ratio and ensure adequate supplementation of essential macro and micronutrients to promote robust microbial growth and EPS production.

Key Takeaway for Treatment Success

Deflocculation is a warning sign that the biological system is under severe stress. Emergency response to deflocculation can include using polymers and augmenting the biomass with bioaugmentation cultures – to increase the living microbial population. Managing it successfully requires a multi-pronged approach focused on maintaining a stable, balanced environment for the microorganisms.