From fine-bubble-diffuser.com

Surfactants, or surface-active agents, are among the most common chemcials used in both households and industrial facilities. Found in everything from personal care products to industrial cleaners, these chemical compounds reduce surface tension between two substances. The emulsifying properties of these surfactants can impact a wastewater treatment plant in multiple ways.

Most common impact of influent surfactants:

- Emulsifying of Fats, Oils, & Grease (FOG) and other insoluble hydrocarbons – defeating normal oil water sepearation efforts. However surfactants can also prove useful in increaseing microbial degradation rates of long chain fatty acids and other insolulbe hydrocarbons by increasing the oil/water interface where microbial activity occurs.

- Damage to microbial cells – surfactants can damage bacterial cell walls. The amount of damage depends on surfactant type and concentrations with cationic quatenary ammonium compounds (Quats) being the most recognized cleaning disinfectant. Concentration is key to predicting the impact on wastewater treatment biomass.

- Reduction in oxygen transfer efficiency (more on this below)

Impact on Oxygen Transfer (OTR)

Surfactants can significantly impact oxygen transfer in various processes, especially in wastewater treatment systems. Here are some key points:

- Reduction in Mass Transfer Rates: Surfactants can decrease the overall gas-liquid volumetric mass transfer coefficient (KLa) by increasing interfacial rigidity and reducing internal gas circulation and interfacial renewal rates.

- Concentration Dependency: The impact of surfactants on oxygen mass transfer varies with concentration. At low concentrations (0-5 mg/L), there is a significant decrease in KLa, while at higher concentrations (10-20 mg/L), the KLa value may recover somewhat.

- Type of Surfactant: Different types of surfactants (anionic, cationic, and non-ionic) have varying effects on oxygen mass transfer. For example, SDBS (Sodium Dodecylbenzene Sulfonate) has a higher KLa value compared to SDS (Sodium Dodecyl Sulfate), Tween20, and CTAB (Cetyltrimethylammonium Bromide).

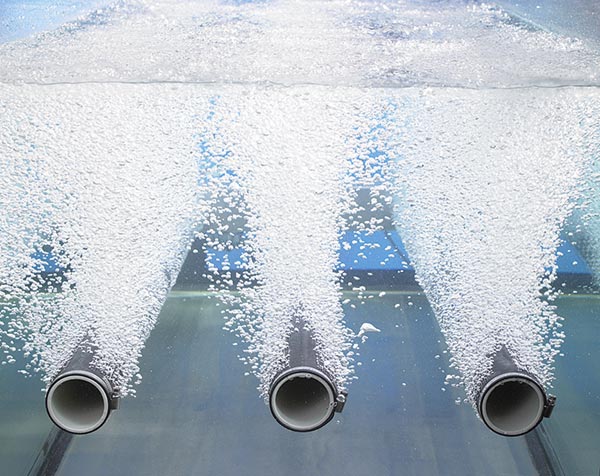

- Bubble Size and Production: Surfactants can promote the production of smaller bubbles, which can improve the mass transfer coefficient by enhancing bubble surface viscosity.

Good Reference on Oxygen Transfer Impact

Chen, X., Liu, Gh., Fan, H. et al. Effects of surfactant contamination on oxygen mass transfer in fine bubble aeration process. Korean J. Chem. Eng. 30, 1741–1746 (2013). https://doi.org/10.1007/s11814-013-0092-x